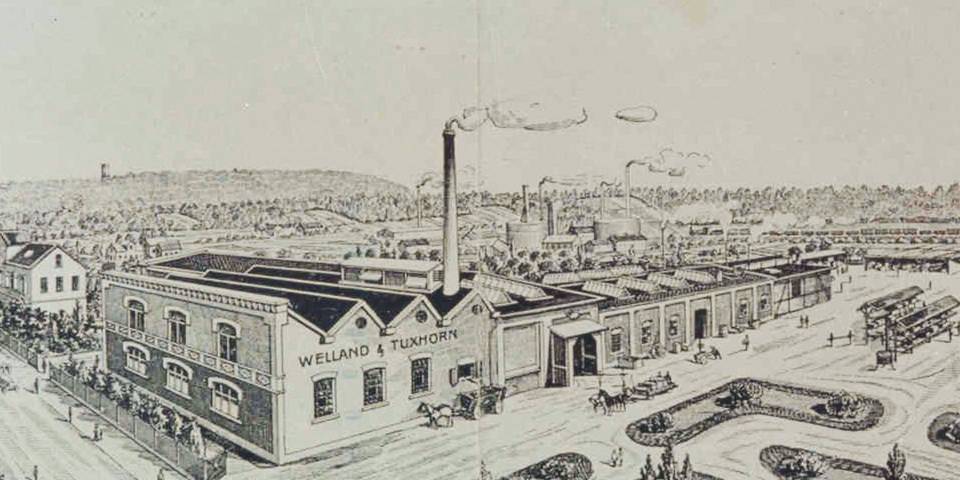

1901

The company is founded by Heinrich Welland at Niedernstraße 123 in Bielefeld.

The production range consists of shut-off valves, gate valves and cast-iron and copper-alloy water cocks.

The company has its own foundry.

1932

Siemens develops dial regulators and servo motors. Welland & Tuxhorn produces the first automatically actuated control valve, which becomes increasingly important in the growing automation of controlled systems, especially in the power generation industry.

1950s

1951

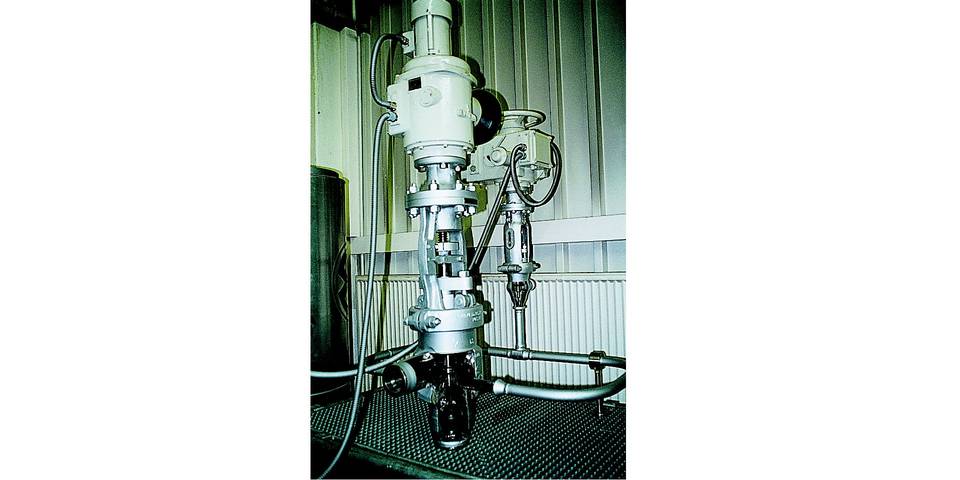

Welland & Tuxhorn and Siemens jointly develop the steam converting valve, the first to regulate the temperature and steam pressure in a single housing.

This invention is put into practice by Welland & Tuxhorn, developing the first steam converting valve with high-pressure injection.

By 1961, the 1000th steam converting valve has already been delivered!

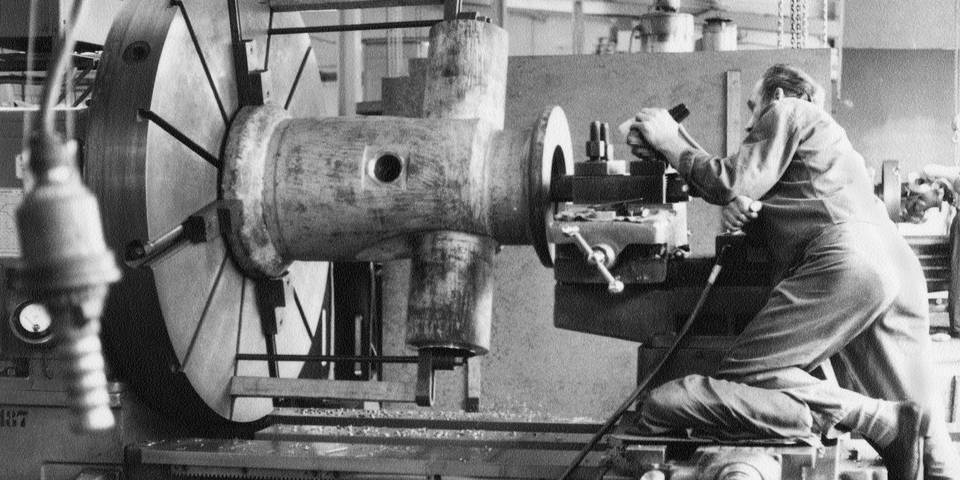

1952-1968

The customer service and assembly department is established. Higher demands due to increased operating parameters mean forged steels replace cast steel. Welded joints replace flanged connections. Welding equipment, thermal treatment facilities and X-ray systems are introduced at Welland & Tuxhorn.

1960s

1960

The steam converting valve is refined to a high- and low-pressure bypass station.

1969

Heinrich Welland jr. leaves Welland & Tuxhorn: The company is taken over by Otto Spindler, an entrepreneur and valve manufacturer from Bielefeld.

1965

Welland & Tuxhorn successfully develops the perforated cage for valve technology: an invention that is soon used by other valve manufacturers. Production of special valves for primary and secondary cycles in nuclear power stations. Construction of a large new production and warehouse facility with an office wing.

1970s

1974

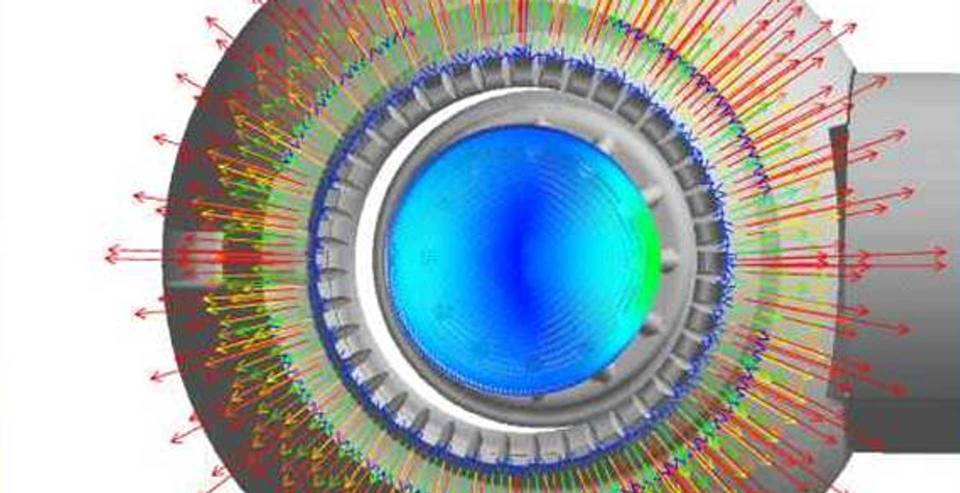

Cooperation with scientific institutes performing fundamental research into flow processes in pipes and valves. The results are used in the design of special heavy-duty valves.

A neighbouring site with a large hall is purchased for manufacturing large valves.

Computer and CAD systems are introduced. Continuous modernisation of the machinery for manufacturing special control valves.

1990s

1990

Hydraulic actuator systems and compact hydraulics are added to the product range.

1991–2000

Increasing process parameters for power valves place new demands on materials, material combinations, functionality and design. In order to include practical experience in the sizing of valves, Welland & Tuxhorn takes part in the “KOMET 650” research project. To continue meeting the requirements of the international market, Welland & Tuxhorn applies for certification according to the regulations of the American Society of Mechanical Engineers (ASME), and becomes the first German control valve manufacturer to receive three important certificates (S,U, PP).

2007

Participation in the GKM HWT 725°C research project funded by the German Ministry of Trade and Industry to test materials and valves at steam temperatures up to 725°C at the Grosskraftwerk Mannheim power plant.

The objective is to improve efficiency in coal-fired power plants.

2010

Completion of the new building and expansion of capacity for assembly, welding, coating, storage and order picking. The new building helps the company cope with constantly increasing exports and order books.

2011

In May 2011 Welland & Tuxhorn was awarded a contract to supply bypass control valves for three blocks of the Ivanpah Solar Electric Generating Facility in California. It is a solar tower project, where a large array of mirrors reflects sunlight to a receiver at the top of the tower, where water is heated to steam with at around 160 bar / 540 °C. This steam drives a combined steam turbine and generator with a capacity of 392 megawatts.

2012

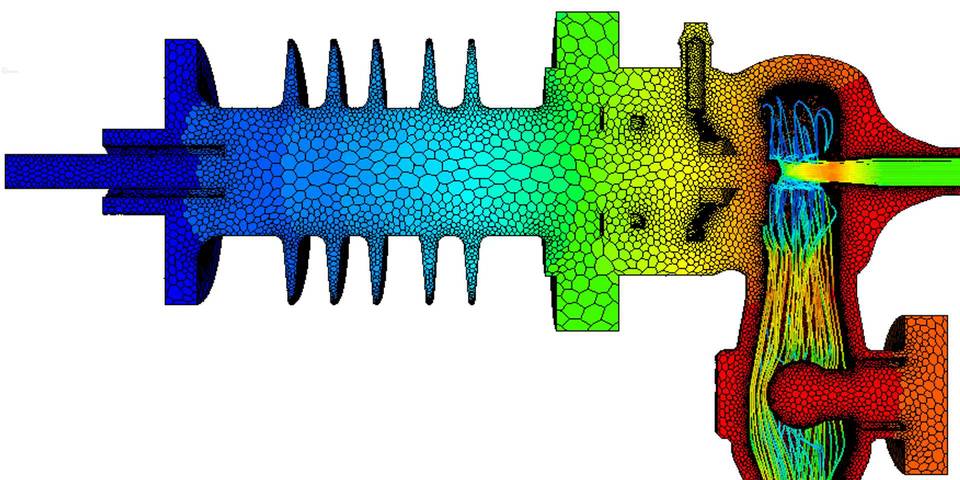

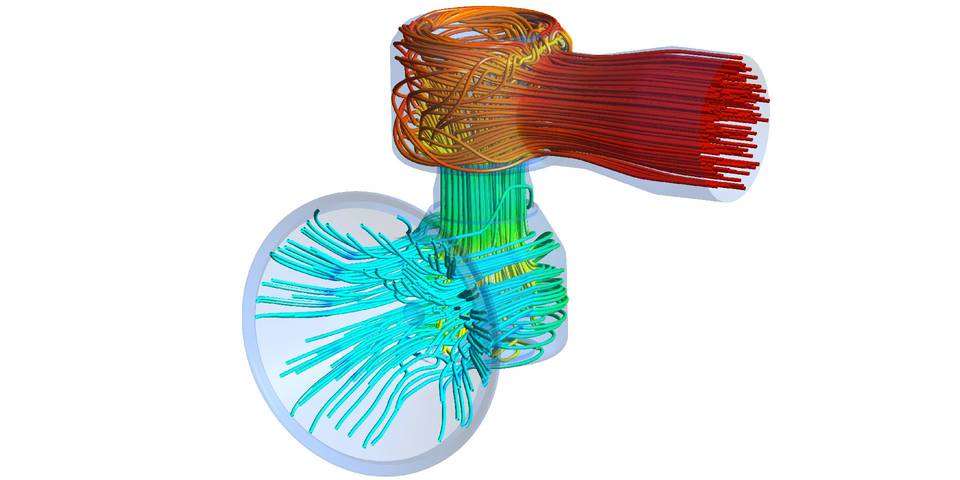

From now on, CFD and FEM calculations and numerical simulations are carried out internally at Welland & Tuxhorn.

In January 2012, Welland &Tuxhorn was awarded a contract to supply key components for the Ras Al Khair combined cycle power plant with connected seawater desalination plant in Saudi Arabia. With an installed capacity of 2400 MW, it will supply electricity for an aluminium smelting plant, as well as around billion litres of drinking water daily for the five million inhabitants of the capital city Riyadh.

2022

Since 01.01.2022, Dr. Martin Wienströer is the sole chairman of Welland & Tuxhorn AG.

Today

Welland & Tuxhorn has become one of the leading manufacturers of special control valves for the power generation and power-consuming industries. For more than 100 years, its dedication, expertise and willingness to take on new challenges have been decisive factors in making our company known in Germany and abroad for its state-of-the-art, high-quality products.

Today, special control valves from Welland & Tuxhorn are in operation on every continent!