HP bypass

Tasks

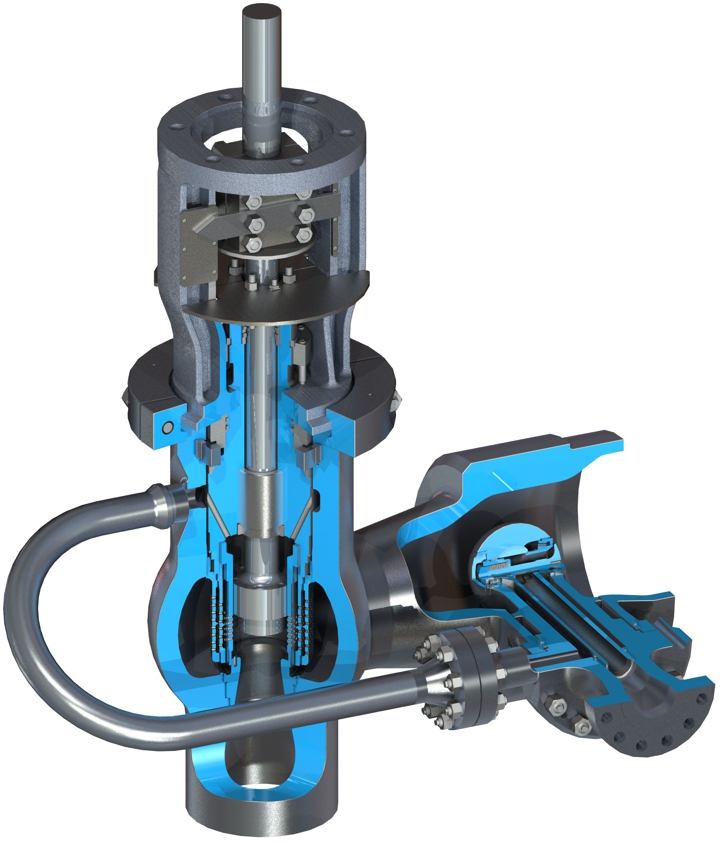

HP bypass with secondary injection and safety function

HP bypass with secondary injection type 700

Ensures safe flow through the reheater and independent operation of the steam generator, even when the turbine inlet is closed. Takes over live steam regulation during start-up and shutdown, as well as during load shedding and malfunctions. During variable pressure operation, also maintains the safety functions if the boiler design pressure is exceeded.

HP bypass with secondary injection type DUV-C4

Ensures safe flow through the reheater and independent operation of the steam generator, even when the turbine inlet is closed. Takes over live steam regulation during start-up and shutdown, as well as during load shedding and malfunctions. During variable pressure operation, also maintains the safety functions if the boiler design pressure is exceeded.

Versions

HP bypass with secondary injection type 700

Forged housing with designs optimised by FEM analysis

HP bypass with secondary injection type DUV-C4

Forged housing in angled form

Advantages

HP bypass with secondary injection and safety function

HP bypass with secondary injection type 700

- Steam pressure and steam temperature just after the injection point in the cold reheater

- Integrated motive steam nozzle for optimum steam conversion throughout the load range

- Easily replaceable interior parts for simple maintenance

HP bypass with secondary injection type DUV-C4

- Integrated motive steam nozzle for optimum steam conversion throughout the load range

- Individual adaptation of all restrictor stages to the operating parameters

- Rapid steam cooling, particularly at partial load

- Installed silencers for low-noise and low-vibration operation

- Low cooling water pressure – easily replaceable interior parts for simple maintenance

IP/LP bypass

Tasks

IP/LP bypass with secondary injection, type E20

The IP/LP bypass station connects the hot reheater in the bypass to the IP/LP turbine with the condenser. If the turbine is not in operation during start-up and shutdown, the steam generated in the reheater must be discharged via the IP/LP bypass station to the turbine condenser, bypassing the medium and low-pressure turbine . The secondary injection cools the steam from the hot reheater sufficiently to ensure that the condenser does not suffer any damage.

Versions

Forged housing in angled form

Advantages

- The pressure-controlled nozzles open sequentially for optimum cooling throughout the entire load range

- Optimised spray angle and minimal droplet size

- Compact design with control piston to reduce steam pressure

- All wear parts can be replaced on site

- Installed silencers for low-noise and low-vibration operation

- Suitable for high-temperature applications

- Available with dump tube designed for specific application

The cooling water is injected via pressure-controlled nozzles according to the steam flow. Depending on the cooling water flow, the nozzles in the centre are opened first. The other nozzles are opened as the cooling water flow increases. The axially aligned nozzles in the steam flow ensure an even temperature distribution in the exhaust steam pipe.

For large outlet diameters, the special solution Type E40 is available.

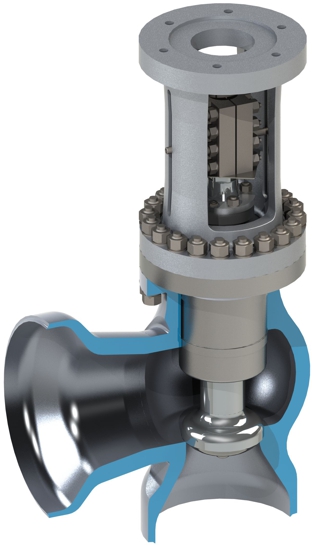

Reheater safety valve

Tasks

Reheater safety valves prevent excess pressure in the reheater. When the valve opens, the hot reheater steam is blown off via the connected rising pipe and attached silencer through the roof into the atmosphere. The valves thus interrupt the otherwise closed water-steam cycle. Unlike the HP/IP/LP bypass valves, there is no steam cooling.

Versions

Forged valves in angled form

Advantages

- Simple, reliable design

- Safety function with cup spring assembly in the positioning cylinder

- Disc spring assembly and steam pressure act in an upwards direction to open the valve safely

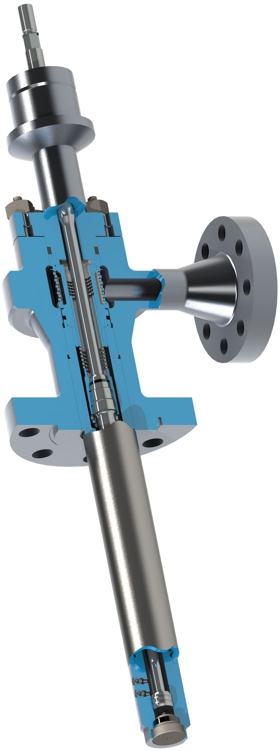

Injection cooler

Tasks

High-temperature injection coolers control the temperatures in boiler (high pressure) superheaters and reheaters.

Versions

Forged housing with flange connections or welded ports

Advantages

The regulated injection coolers are a unit consisting of a cooling water control valve and a nozzle head.

- Fine misting of cooling water even at partial load

- Exact metering of injection flow for precise temperature adjustment

- Piston rings seal unused nozzles for high adjustment ratio (1:25)

- Pre-throttling in 1 to 3 control stages ensures low wear even with steep pressure gradients

- Drip-tight in closed position

- Upstream dirt filter as standard

- All installed parts can be replaced without machining

Application: Separate, for temperature control