Our hydraulics: powerful, precise and fast

The advantage of the hydraulic positioning cylinder, the most important element in the hydraulic system, is its high relative strength, which means it can transmit great forces in a small space.

The energy from the hydraulic fluid, which is supplied by a hydraulic pressure accumulator or a hydraulic pump, is converted by flow regulating elements into a linear force which can be precisely controlled to directly open or close the connected valves without any significant loss of efficiency. Very smooth, precise and long movements (strokes) are also possible, because the extent to which hydraulic fluid can be compressed is so low as to be negligible in technical applications. This also allows easy speed control under load within a large adjustment range.

Complete integration: everything from a single source

Our system is a combination of valves, actuators and electrohydraulic components. Our expertise is the basis for integrating and selecting the subcomponents. By integrating and correctly combining the subcomponents, we ensure that that you, the customer, do not have to deal with any additional interfaces: this means less outlay, better safety, shorter waiting times, shorter routes and fewer misunderstandings.

Tasks

- Safely and reliably actuating main control valves in control loops of power plants and many other types of process engineering systems.

- Performing complex regulation and control tasks, also using a compact PROFIBUS connection.

- Integration of safety functions such as turbine, boiler or condenser protection.

- Providing emergency strokes if the auxiliary power fails.

Solutions

Solutions for all kinds of applications: To ensure that a system does optimally perform its tasks, its subcomponents must be perfectly tuned to each other. Our hydraulic actuators are available in different versions to cater for the varying requirements of different systems. Our models range from compact actuators for installing on a single valve to separate actuator systems for up to 18 valves.

Design

It is possible to implement the failsafe functions or those described in DIN EN ISO 4126-5 (controlled safety pressure relief systems, CSPRS) by using spring-loaded cylinders or by adding our type-tested safety valve control system. Using mostly standardised elements and assemblies and being flexible in arranging them results in a very robust and reliable design. Other advantages of our hydraulic systems are their long service life and low maintenance, with the sliding parts lubricated by the hydraulic fluid.

Additional safety

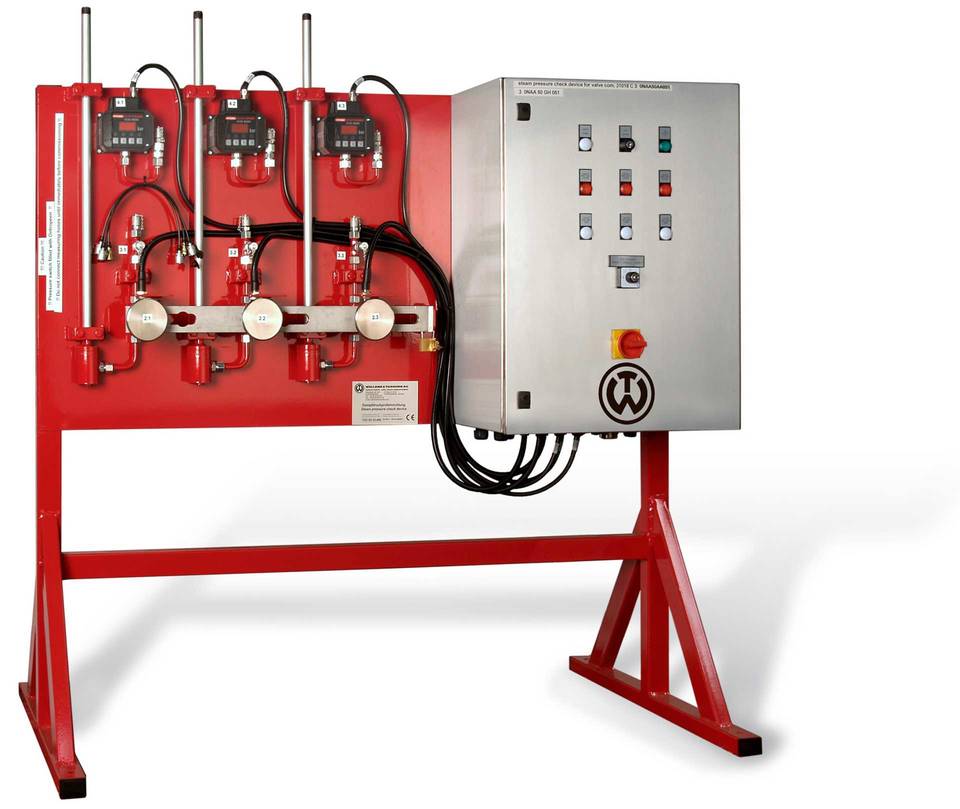

Electrohydraulic safety valve control system

Our TÜV-certified electrohydraulic safety valve control system reliably protects your plant, boiler, pipes and downstream systems from overpressure. The control system complies with the DIN EN ISO 4126-5 safety standard and is certified with the type-test approval mark TÜV-SV 09-886 and SIL3 acc. to DIN IEC 61508. The safety system is an interaction between the following components: Steam pressure test device, pressure relief valves (safety block) on the hydraulic station and cup spring assembly in the actuator. The steam pressure test device monitors the process pressure using a 1-of-3 safety device. When it is triggered, the safety chain is de-energised, equalising the pressure in the hydraulic system so that the valve can be safely moved to its end position by the cup spring assembly. Because the system uses the quiescent current principle, safety is completely guaranteed even in the event of power failures. The hard-wired system is controlled without any software. This increases the reliability of the entire system. We supply you with the version of steam pressure test device that is suitable for you, either as a wall-mounted unit, completely enclosed or with supports for free-standing installation. These components each consist of a combination of 3 pulse lines, shut-off valves, pressure switches and an indicator panel as the interface to the hydraulic station. This means we can guarantee the maximum possible safety for your system, your staff and the environment.

Advantages of Welland & Tuxhorn hydraulic actuating systems

- Everything from one single source

- Excellent control

- Very high actuating force

- Very high rigidity

- Fast actuation speeds

- Type-tested according to DIN EN 4126-5

- Cup springs for safety position

- Modular design for flexible configuration

- Double-action cylinder

- SIL certification for safety components